Our Vee Brick product line is part of a growing trend to use thin brick in both traditional ceramic wall tile type installations and also in all types of wall panel systems. This shift away from traditional brick (full bed depth) masonry is being driven by economics. The use of thin brick can provide tremendous cost savings. Foundations and structural members can be down-sized because of reduced weight. With many panel systems, installation labor can be reduced because panels can be made indoors, off the job site, without trained masons. Panel utilization shortens construction time and can eliminate scaffolding costs. Also, thin brick can be easily used for interior walls, including back splashes, where full brick would not be practical. Also, buildings incorporating thin brick panels lend themselves to earthquake tolerant construction features. All of this is accomplished without giving up the rich look and dignity of traditional brick construction or the potential of dramatic architectural statement featuring the vivid natural colors of our Vee Brick product line.

The use of thin brick veneer masonry has evolved over many years. Traditionally, thin brick has been installed in the same way as ceramic wall tile (i.e., on to a vertical substrate which could be masonry or interior or exterior stud wall - steel or wood). These types of installations continue to be used with the coursing of the veneer brick being set by a metal panel nailed to the wall, spacers or the rope method. Ceramic tile installation requirements should be followed for these types of installations.

Jobsite cast tilt-up panels are made in the same way as precast panels except that form liners are made with less expensive disposable materials. As with precast panels, both Marion's 9/16" or 15/16" thick Vee Brick work well with liners that accept normal sizing variations.

Since the early 1970s, numerous thin brick wall panel systems have been developed utilizing many different types of materials. Systems are now available with panels made from metal, insulation foam, cementitious board, masonite, plywood, and composite board. Most of these systems were developed primarily for residential use, both new construction and especially for remodeling. Owners, architects, and builders should carefully select a system which will work best for each project.

Marion's Vee Brick can be used in all of the above-described methods and is especially well suited for precast panels.

Failure to follow recommendations will void our warranty.

Marion Ceramics' Vee Brick products are available in a broad spectrum of beautiful colors, which are all compatible for color coordinating and/or contrasting design statements. Our palette of colors includes eight nine tones and one ironspot to make up our Vee Brick Classics colors. Five colors make up our Vee Brick Rustics line. The Vee Brick Rustics products are naturally flashed using reduction firing techniques perfected over decades - no artificial look that often comes with chemical flashes. The hard-fired colors of our Vee Brick are colorfast and will not fade with exposure to sunlight and weather as will occur with pigmented cementitious thin brick. Marion Ceramics takes the extra care required to formulate each body and to double mix during grinding to maintain color consistency.

Significantly, Marion offers factory blending of its Tumbled Vee Brick to accommodate designers wanting the variegated color ranges of used brick which are so popular for residential thin brick applications. Architects can specify the percentage of each color to be included for unique blends to produce any desired effect.

* Due to variations in photography and in online digital images, final color selections should be made from actual product samples prior to purchase.

Vee Brick Classics colors have been developed over many years to fill the needs of homeowners and thin brick users. Our Vee Brick product line is especially popular with architects and designers because care is taken to produce a wide range of attractive colors for unmatched and unlimited design possibilities.

The first in the Vee Brick Classics line are our two reds: 200Plantation Red, which is exceptionally vivid and clear; and 250 Havana Red, having deep reddish brown tones which match many residential face brick. Following those, we offer a chocolate brown color 410 Gunstock Brown, then introduce light burning raw materials to perfect our buff color 600 Chino and our terra-cotta 610 Sunlit Earth. Sunlit Earth is also the base body used to produce our Indian 615 Copper ironspot color.

The balance of our Vee Brick Classics colors consists of four of the most beautiful architectural brick colors available including our recently introduced white 710 Seashell, tan 820 Sahara and two grays: 760 Academy Grey and 510 Cobblestone.

Our exceptional range of colors has proven to be especially appealing when both flashed and unflashed colors are blended.

All of Marion Ceramics' Vee Brick Rustics colors are natural gas flashed and made with the same body formulas used in the matching clear tone colors. The resulting variegated tones of these perimeter flashed colors make for a special warmth and rustic feel that can only be achieved with natural materials.

Our two reds are flashed to produce the 300 Tavern Flash and 255 Magnum Flash colors. Our brown flash is 400 Colonial Blend. The 655 Sundance is made with our buff body, and 675 Tangier color is fired from our terra cotta body.

All of our colors are compatible with similarly colored residential face brick and work well with architectural and commercial projects using matching and/or contrasting face brick or other facing materials.

Marion's Vee Brick product line is available in the modular brick size (2 1/4" x 7 5/8" x 9/16") along with matching corners. Extra care is taken in the manufacturing process to ensure that the long leg of our flashed corners is a perfect match for our flashed thin brick. Also, some unflashed corners are blended with flashed corners to reduce the possible zipper look at the corner of buildings.

Marion Ceramics also provides several thin brick options by special order. We offer our thin brick product line in 15/16" thickness for precast panel jobs where architects are concerned with bond strength. This thickness allows these units to be further imbedded into the panels for unequaled bonding. We can also produce thin brick in the closure size (3 5/8" x 7 5/8" x 9/16") along with closure corners. Our process allows us to produce thin brick up to 2" in thickness, which provides the design opportunity of wall relief dimensions. We also offer matching face brick to complement our thin brick product line.

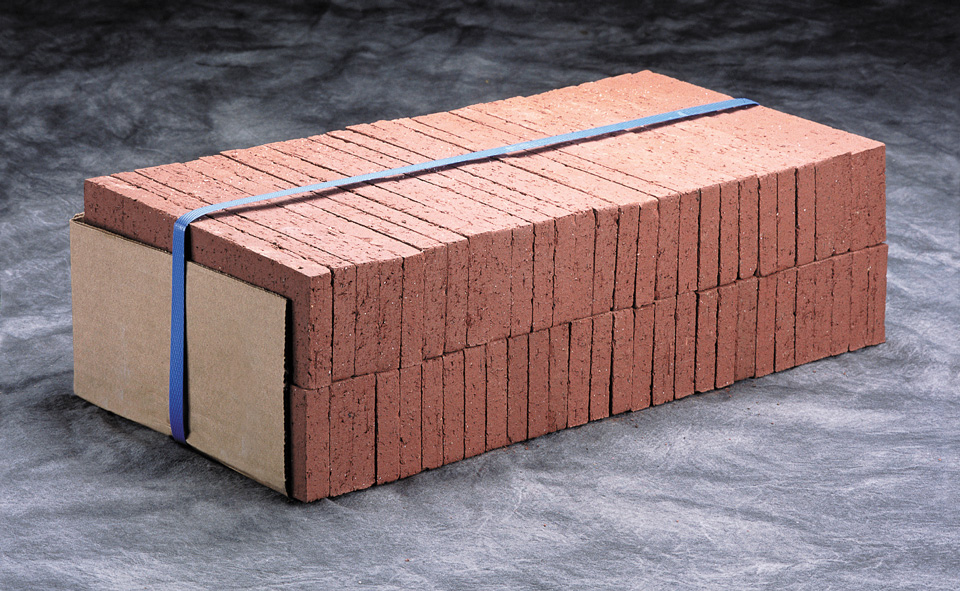

Our Vee Brick products are stacked in cardboard trays and secured in place with a plastic strap. The cartons are then stacked on a wooden pallet. A waterproof top sheet is then placed on the pallet before being stretch-wrapped. The resulting pallet package provides the best possible protection from the weather.

Brick Pavers - Marion Ceramics offers brick pavers that perfectly match our Vee Brick products. Pavers come in 9/16", 15/16", and 2 1/4" thicknesses.

Coping - Marion Ceramics also produces 2 1/4" thick coping in seven of the same colors as our Vee Brick products. Coping can be used to add special architectural details to any job. In addition to pool edging, our coping shapes have been used for wall and column caps, water tables, step treads, and unique column designs.

Failure to follow recommendations will void our warranty.

In order to ensure your complete satisfaction with our Vee Brick products, it is very important that installers and owners comply with the following recommendations:

Color variations are a natural characteristic of all fired clay products and are inherent in our Vee Brick products. At the job site, we recommend mixing Vee Brick from several cartons to provide a natural blend of color shades. For jobs requiring more than one pallet, blending from cartons from each pallet is recommended. Our clear tone colors will have a slight range of color. Our flashed colors will have a broader range of colors.

Extra care is taken in the manufacturing process to ensure that the long leg of our corners do not have imperfections or cross hack marks even for flashed corners. This extra step enables Marion Ceramics to produce flashed corners with the long leg matching our flat tile. Unavoidably, the short legs of flashed corners do not perfectly match the long leg. It is therefore recommended for jobs incorporating corners and utilizing our flashed colors, that care be taken in selecting corners as they are installed to include unflashed units to avoid a zipper appearance. Marion Ceramics now includes some unflashed corners which are blended into our inventory of flashed corners at the factory. Do not install any Vee Brick, flats or corners, which are not satisfactory in every way.

Our Vee Brick are manufactured to meet or exceed ASTM C1088 specifications for Type TBS, Grade Exterior. Our production techniques enable us to exceed the dimensional tolerances allowed under this specification. However, it is recommended that in all Vee Brick installations, both traditional ceramic wall tile type installations and in all types of wall panel systems, that allowances be made to accommodate normal dimension variations in thin brick.

It is recommended that all ceramic wall tile type installations follow the specifications outlined in the current Tile Council of North America's "Handbook for Ceramic Tile Installation." Also, after Vee Brick are installed, but before grouting, we recommend that an appropriate grout release product is used. After Vee Brick are grouted, final cleaning should be done with either sulfamic acid crystals or a factory premixed brick cleaner, followed by complete neutralization with clean, clear water. Precast panel and wall panel system installations should follow industry and manufacturer's instructions and specifications.

Due to variations in photography, digital imaging, and printing processes, final color selections should be determined based on actual product samples before purchase. Image colors displayed on this web site may not properly represent actual colors of products due to differences in viewing devices, display settings, and hardware capabilities.

Failure to follow recommendations will void our warranty.

| Size (Nominal) | PCS /Carton | Sq.Ft /Carton | Ln.Ft/ Carton | PCS /Pallet | Sq.Ft /Pallet | Ln.Ft /Carton | WT /Carton*** | WT /Pallet**** |

|---|---|---|---|---|---|---|---|---|

| Flats 2 1/4" x 7 5/8" x 9/16" 6.86 pcs/Sq.Ft* |

56 | 8.16 | N/A | 4,480 | 653 | N/A | 41.25 lbs | 3,300 lbs |

| 90° Corners 2 1/4" x 7 5/8" x 3 5/8" x 9/16" 4.57 pcs/Ln.Ft* |

28 | N/A | 6.13 | 1,568 | N/A | 339 | 29.68 lbs | 1,661 lbs |

| Closure Flats 3 5/8" x 7 5/8" x 9/16" 4.5 pcs/Sq.Ft* |

28 | 6.22 | N/A | 2,240 | 497.6 | N/A | 33.41 lbs | 2,673 lbs |

| 90° Closure Corners ** 3 5/8" x 7 5/8" x 3 5/8" x 9/16" 3 pcs/Ln.Ft* |

16 | N/A | 5.33 | 960 | N/A | 320 | 22 lbs | 1,360 lbs |

| Face Brick ** 2 1/4" x 7 5/8" x 3 5/8" 3 pcs/Ln.Ft* |

7 | 1 | N/A | 560 | 81.6 | N/A | 28 lbs | 2,160 lbs |

| Edge Cap ** 2 1/4" x 7 5/8" x 3 5/8" x 9/16" 1.5 pcs/Ln.Ft* |

10 | N/A | 1.5 | 400 | N/A | N/A | 14 lbs | 743 lbs |

* Square foot prices based on 3/8" grout joints

** Available by Special Order.

*** Weights vary due to moisture and body formulations

****Add 56 #'s for the pallet

For Additional Information about our Products or Pricing, Contact a Dealer in your Area.